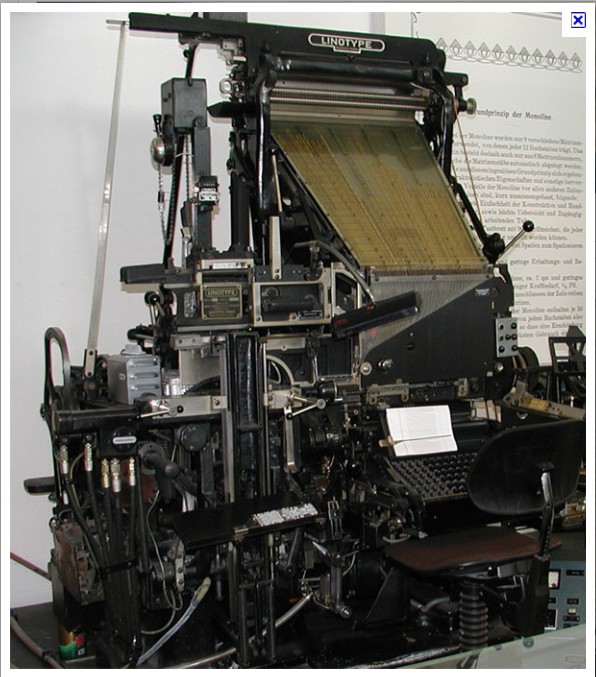

The Linotype Machine

My interest in, and amazement by, the Linotype machine, began in late 1950’s, when my friend and fellow night movie usher, Dennis, and I finish our day, around midnight, at Abilene, Texas’ Paramount Theatre and visited his three brothers who worked, just three blocks south, in the production department of the Abilene Reporter News newspaper. Newspaper employees included Dennis’ brothers: Steve, manager of the production department; Jim, Linotype machine operator; Dwight “Ike” newspaper pressman. After a complete tour of the production department, I discovered that of all the machines and processes that were used to compose and print a newspaper, the Linotype was by far the most impressive.

My first image and smell of (odor produced by the molten Eutectic linotype metal alloy, a mixture of Lead, Tin and Antimony) these machines was both baffling and enlightening. I had helped overhaul automobile engines and thoroughly understood the technology but, the complexity of this machine far surpassed any mechanical thing that I had ever seen. After watching Jim at the Linotype’s 90-character keyboard, for a few moments, I began to get the rhythm and partially learn the procedure, but without the ability to totally understand all, of the mechanics or processes of the machine, as it produced one “line-of-type” at a time.

One partial “line-of-type” – the finished product.

During the next three years, Dennis and I often visited the newspaper production department, always in the wee hours of the morning, when our presence could go unnoticed, by the newspaper management (beyond Steve) until our graduation from High School. During the 1960s, most of the Linotype machines and associated equipment were phased out, of printing newspapers, in favor of automated typesetting which produced a half-cylinder of finished type metal which produced one whole page of the newspaper during each one-half revolution of the newly installed cylindrical presses, which Ike was so proud to operate. Steve was able to purchase Linotypes and some other outdated equipment, from the Abilene Reporter, and extend its life for another decade or so, in several smaller towns, around Abilene, where Steve owned and published local newspapers, during the daylight hours, for these smaller communities.

My first job after graduating high school and while attending College was Asst. Manager (later Manager) of a Drive-Inn Theatre. Part of my duties at the Drive-Inn involved ordering and supervising the printing of various promotional movie and theatre event handbills and etc. It was during this period that I received continuing education on the Linotype. After meeting and becoming business friends with Harry who was the Linotype operator at Abilene’s The Pender Company, which had been chosen to do most of the Theatre’s printing jobs.

As a regular customer, I was allowed to enter the print shop area where I talked to Harry who was a very proficient Linotype operator and seemed to enjoy his chosen craft, very much. Harry always had great answers for my thousands of questions about the Linotype operation, capabilities and “tricks of the trade.”

All of this exposure to the Linotype, had peaked my interest, to such an extent that I started doing research, about the Linotype machine. However, I found very little out about the machine mechanics. I did learn that a German clock maker, Ottmar Mergenthaler, who had emigrated to the United States in 1872, invented the Linotype with funding and help from others. The first machines were sold to the New York Tribune Newspaper, in 1886.

Linotype Machine – this whole complicated machine’s only task is to produce a single line-of-type, one at a time.

Linotype Machine – this whole complicated machine’s only task is to produce a single line-of-type, one at a time.

Initially, The Mergenthaler Linotype Company was the only company producing linecasting machines, but as Patents expired, other companies would begin manufacturing similar machines. The Intertype Company produced the “Intertype”, a machine closely resembling the Linotype, and using the same basic process as the Linotype, started production around 1914. It was actually the Intertype brand, of Linotype, that I was latter to own and learn to operate.

In 1983, I purchased a Printing Company which had 12 people in the printing department, including two who operated the two Linotypes (Intertypes), which produced type for the three letterpress. This gave me the chance to actually operate and to better understand the internal working of the Linotype. While I had no actual experience, in the printing business before buying the company, after a quick study, I successfully operated the Printing Company. After three years of ownership, my other business interest, reduced my available time to the point that encouraged me to reluctantly sell the printing business. However, to this day, I still have many fond memories and a lot of printing memorabilia which unfortunately does not include a whole intact Linotype machine (only a part of one).

These machines played a huge role in educating and informing the world but have been almost totally replaced by equipment with computer brains.

If you are not familiar with the operation of the Linotype machine and this little piece of history has interested you, I think you will find this short video entertaining and educational.